Page Contents

Sodium-ion batteries are present process an essential interval of commercialization as industries from automotive to power storage wager large on the expertise. Established battery producers and newcomers are jostling to get from lab to fab with a viable various to lithium-ion. With the latter commonplace for electrical mobility and stationary storage, new expertise should supply confirmed benefits. Sodium ion seems effectively positioned, with superior security, uncooked materials prices, and environmental credentials.

Sodium ion gadgets don’t want essential supplies, counting on plentiful sodium as an alternative to lithium, and no cobalt or nickel. As lithium-ion costs rose in 2022, amid predictions of fabric shortages, sodium ion was tipped as a rival and curiosity stayed robust, whilst lithium-ion costs have begun to fall once more.

“We’re at present monitoring 335.4 GWh of sodium ion cell manufacturing capability out to 2030, highlighting that there’s nonetheless appreciable dedication to the expertise,” mentioned Evan Hartley, senior analyst at Benchmark Mineral Intelligence.

In Could 2023, the London-based guide had tracked 150 GWh to 2030.

Cheaper

Sodium ion cells, produced at scale, might be 20% to 30% cheaper than lithium ferro/iron-phosphate (LFP), the dominant stationary storage battery expertise, primarily because of plentiful sodium and low extraction and purification prices. Sodium-ion batteries can use aluminum for the anode present collector as an alternative to copper – utilized in lithium-ion – additional decreasing prices and provide chain dangers. These financial savings are nonetheless potential.

“Earlier than sodium-ion batteries can problem present lead acid and lithium iron phosphate batteries, trade gamers might want to scale back the expertise’s price by bettering technical efficiency, establishing provide chains, and reaching economies of scale,” mentioned Shazan Siddiqi, senior expertise analyst at United Kingdom-based market analysis firm IDTechEx. “Nation’s price benefit is barely achievable when the size of manufacturing reaches a producing scale similar to lithium-ion battery cells. Additionally, an additional worth drop of lithium carbonate may scale back the worth benefit sodium provides.”

Sodium ion is unlikely to supplant lithium ion in functions prioritizing excessive efficiency, and can as an alternative be used for stationary storage and microelectrical autos. S&P World analysts anticipate lithium ion to provide 80% of the battery market by 2030, with 90% of these gadgets primarily based on LFP. Sodium ion may make up 10% of the market.

Proper decisions

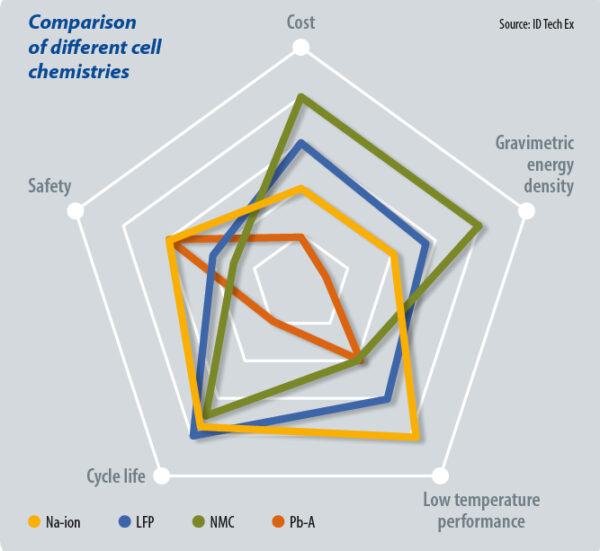

Researchers have thought about sodium ions for the reason that mid-twentieth century and up-to-date developments embrace enhancements in storage capability and machine life cycle, in addition to new anode and cathode supplies. Sodium ions are bulkier than lithium counterparts, so sodium ion cells have decreased voltage in addition to decreased gravimetric and volumetric power density.

Sodium ion gravimetric power density is at present around 130 Wh/kg to 160 Wh/kg, however is anticipated to high 200 Wh/kg in the future, above the theoretical restrict for LFP gadgets. In energy density phrases, nonetheless, sodium-ion batteries may have 1 kW/kg, increased than nickel-manganese-cobalt’s (NMC) 340W/kg to 420 W/kg and LFP’s 175 W/kg to 425 W/kg.

Whereas a sodium ion machine’s lifetime of 100 to 1,000 cycles is decreased than LFP, Indian developer KPIT has reported a lifespan with 80% capability retention for six,000 cycles – depending on cell chemistry – similar to lithium-ion gadgets.

“There’s nonetheless no single profitable chemistry inside sodium-ion batteries,” mentioned IDTechEx’s Siddiqi. “Several R&D efforts are being undertaken to seek out the proper anode/cathode energetic materials that enable scalability past the lab stage.”

Referring to United States-based security science organization Underwriter Laboratories, Siddiqi added that “UL standardization for sodium ion cells is, subsequently, nonetheless some time away and this makes OEMs [original equipment manufacturers] hesitant to decide to such an expertise.”

Prussian white, polyanion, and layered oxide are cathode candidates that include cheaper supplies than lithium-ion counterparts. The previous, utilized by Northvolt and CATL, is broadly out there and low cost however has comparatively low volumetric power density. United Kingdom-based firm Faradion makes use of layered oxide, which guarantees increased power density however is tormented by capability fade over time. France’s Tiamat makes use of polyanion, which is extra steady however options poisonous vanadium.

“The vast majority of cell producers planning sodium ion battery capability will probably be utilizing layered oxide cathode expertise,” mentioned Benchmark’s Hartly. “71% of the [cell] pipeline is layered oxide. Equally, 90.8% of the sodium ion cathode pipeline is layered oxide.”

Whereas cathodes are the important thing price driver for lithium-ion, the anode is the most costly element in sodium-ion batteries. Arduous carbon is the usual alternative for sodium ion anodes however manufacturing capability lags behind that of sodium ion cells, ramping up costs. Arduous carbon supplies have not too long ago been derived from various precursors corresponding to animal waste, sewage sludge, glucose, cellulose, wooden, coal, and petroleum derivatives. Artificial graphite, a typical lithium-ion anode material, depends virtually solely on the latter two precursors. With its creating provide chain, exhausting carbon is extra pricey than graphite and represents one of many key hurdles in sodium ion cell manufacturing.

Partially mitigating increased prices, sodium-ion batteries exhibit higher temperature tolerance, notably in sub-zero circumstances. They’re safer than lithium-ion, as they are often discharged to zero volts, decreasing danger throughout transportation and disposal. Lithium-ion batteries are sometimes saved at around 30% cost. The sodium ion has much less fireplace danger, as its electrolytes have the next flashpoint – the minimal temperature at which a chemical can vaporize to kind an ignitable combination with air. With each chemistry that includes comparable construction and dealing ideas, sodium ions can usually be dropped into lithium-ion manufacturing strains and gear.

The world’s main battery maker CATL is integrating sodium ions into its lithium ion infrastructure and merchandise. Its first sodium-ion battery, launched in 2021, had a power density of 160 Wh/kg, with a promised 200 Wh/kg sooner or later. In 2023, CATL mentioned that Chinese language automaker Chery could be the primary to make use of its sodium-ion batteries. CATL advised late in 2023 that it has developed a fundamental trade chain for sodium-ion batteries and established mass manufacturing. Manufacturing scale and shipments will rely on buyer challenge implementation, mentioned CATL, including that extra must be achieved for the massive scale business rollout of sodium ion. “We hope that the entire trade will work collectively to advertise the event of sodium-ion batteries,” mentioned the battery maker.

Cost to sodium

In January 2024, China’s largest carmaker and second-biggest battery provider, BYD, mentioned it had begun development of a CNY 10 billion ($1.4 billion), 30 GWh per 12 months sodium ion battery manufacturing unit. The output will be energy “micromobility” gadgets. HiNa, spun out of the Chinese language Academy of Sciences, in December 2022 had commissioned a gigawatt-hour-scale sodium ion battery manufacturing line and introduced a Na-ion battery product and electrical automobile prototype.

European battery maker Northvolt unveiled 160 Wh/kg-validated sodium ion battery cells in November 2023. Developed with Altris – spun out of Uppsala College, in Sweden – the expertise will probably be used within the firm’s next-generation power storage machine. Northvolt’s present providing is predicated on NMC chemistry. On the launch, Wilhelm Löwenhielm, Northvolt’s senior director of enterprise growth for power storage techniques, mentioned the corporation desires a battery that’s aggressive with LFP at scale. “Over time, the expertise is anticipated to surpass LFP considerably by way of cost-competitiveness,” he mentioned.

Northvolt desires a “plug-and-play” battery for quick market entry and scale-up. “Key actions for bringing this specific expertise to market are scaling the provision chain for battery-grade supplies, which Northvolt is at present doing, along with companions,” mentioned Löwenhielm.

Smaller gamers are additionally doing their bit to carry sodium ion expertise to commercialization. Faradion, which was acquired by Indian conglomerate Reliance Industries in 2021, says it’s now transferring its next-generation cell design to manufacturing. “Now we have developed a brand new cell expertise and footprint with 20% increased power density, and elevated cycle-life by a 3rd in comparison with our earlier cell design,” mentioned Faradion Chief Govt Officer (CEO) James Quinn. The corporation’s first-generation cells demonstrated a power density of 160 Wh/kg. In 2022, Quinn mentioned that Reliance planned to construct a double-digit-gigawatt sodium ion manufacturing unit in India. For now, these plans are nonetheless in place. In August 2023, Reliance Chairman Mukesh Ambani advised the corporation’s annual shareholder assembly that the enterprise is “centered on fast-track commercialization of our sodium ion battery expertise … We’ll construct on our expertise management by industrializing sodium ion cell manufacturing at a megawatt degree by 2025 and quickly construct as much as Giga scale thereafter,” he mentioned.

Manufacturing

Startup Tiamat has moved ahead with its plans to start the development of a 5 GWh manufacturing plant in France’s Hauts-de-France area. In January 2024, it raised €30 million ($32.4 million) in fairness and debt financing and mentioned that it expects to finish the financing of its industrial challenge within the coming months, bringing the entire financing to around €150 million. The corporation, a derivative of the French Nationwide Centre for Scientific Analysis, will initially manufacture sodium ion cells for energy instruments and stationary storage functions in its manufacturing unit, “to meet the primary orders which have already been acquired.” It is going to later goal scaled-up manufacturing of second-generation merchandise for battery electrical car functions.

In America, trade gamers are additionally ramping up their commercialization efforts. In January 2024, Acculon Power introduced collection manufacturing of its sodium-ion battery modules and packs for mobility and stationary power storage functions and unveiled plans to scale its manufacturing to 2 GWh by mid-2024. In the meantime, Natron Power, a derivative out of Stanford College, is meant to start out mass-producing its sodium-ion batteries in 2023. Its objective was to make 600 MW of sodium ion cells at battery producer Clarios Worldwide’s exiting lithium ion Meadowbrook facility, in Michigan. Updates on progress have been restricted, nonetheless.

Funding

In October 2023, Peak Power emerged with $10 million in funding and an administration workforce comprising ex-Northvolt, Enovix, Tesla, and SunPower executives. The corporation mentioned it should initially import battery cells and that was not anticipated to vary till early 2028. “You want round a billion {dollars} for a small scale gigawatt manufacturing unit – assume lower than 10 GW,” Peak Power CEO Landon Mossberg mentioned on the launch. “So the quickest approach to get to market is to construct a system with cells out there from a 3rd occasion, and China is the one place constructing capability to ship sufficient cells.” Finally, the corporation hopes to qualify for home content material credit beneath American Inflation Discount Act.

Some suppliers, corresponding to India’s KPIT, have entered the house with no manufacturing plans. The automotive software program and engineering options enterprise unveiled its sodium-ion battery expertise in December 2023 and launched into a seek for manufacturing companions. Ravi Pandit, chairman of KPIT, mentioned that the corporation has developed several variants with power density starting from 100 Wh/kg to 170 Wh/kg, and probably reaching 220 Wh/kg. “After we began work on sodium-ion batteries, the preliminary expectation of power density was fairly low,” he mentioned. “However during the last eight years, the power density has been going up due to the developments that we and different corporations have been finishing up.

” Others are looking out for provide partnerships. Final 12 months, Finnish expertise group Wärtsilä – one of many world’s main battery power storage system integrators – mentioned that it was looking for potential partnerships or acquisitions within the area. At the time, it was shifting towards testing the expertise in its analysis services. “Our workforce stays dedicated to pursuing new alternatives by way of diversifying power storage applied sciences, corresponding to incorporating sodium ion batteries into our future stationary power storage options,” mentioned Amy Liu, director of strategic options growth at Wärtsilä Power Storage and Optimization, in February 2024.

Nearshoring alternative

Following many mass-production bulletins, sodium ion batteries are actually on the make-or-break level and investor curiosity will decide the expertise’s destiny. IDTechEx’s market evaluation, carried out in November 2023, suggests anticipated progress of a minimum of 40 GWh by 2030, with an extra 100 GWh of producing capability hinging available on the market’s success by 2025.

“These projections assume an impending growth within the [sodium ion battery] trade, which depends upon business dedication inside the subsequent few years,” mentioned Siddiqi.

Sodium ion may supply yet one more alternative to near-shore clear power provide chains, with the required uncooked supplies so available throughout the globe. It seems that practice has already left the station, nonetheless. “As with the early phases of the lithium-ion battery market, the principle bottleneck for the worldwide trade would be the dominance of China,” mentioned Benchmark’s Hartley. “As of 2023, 99.4% of sodium ion cell capability was primarily based in China and this determine is barely forecast to fall to 90.6% by 2030. As coverage in Europe and North America seeks to shift lithium-ion battery provide chains away from China, as a result of reliance on its home manufacturing, so too will a shift be wanted within the sodium ion market to create localized provide chains.”